Photobioreaktor

Part of KSD

KSD works on the development of a low-cost polymer photo bioreactor in the sizes of 1L, 5L, 50L and 100L. In this case we are checking the material compatibility to find both robust and bio compatible materials. Another focus is the automatization of the online control of the process, the development of the upstream process and the downstream process and the evaluation of the up- and downstream processes.

About Cyanofactory

Further information: http://cyanofactory.eu/

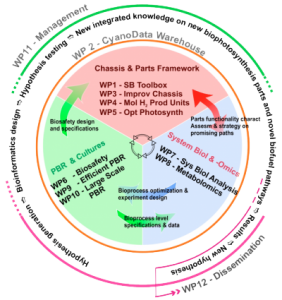

CyanoFactory brings together ten selected leading, highly complementary European partners with the aim to carry out integrated, fundamental research aiming at applying synthetic biology principles towards a cell factory notion in microbial biotechnology.

The vision is to build on recent progress in synthetic biology and develop novel photosynthetic cyanobacteria as chassis to be used as self-sustained cell factories in generating a solar fuel. This will include the development of a toolbox with orthogonal parts and devices for cyanobacterial synthetic biology, improvement of the chassis enabling enhanced growth and robustness in challenging environmental conditions, establishment of a data warehouse facilitating the modelling and optimization of cyanobacterial metabolic pathways, and strong and novel bioinformatics for effective data mining. To reach the goal, a combination of basic and applied R&D is needed; basic research to design and construct the cyanobacterial cells efficiently evolving H2 from the endless resources solar energy and water, and applied research to design and construct the advanced photo bioreactors that efficiently produce H2.

Biosafety is of highest concern and dedicated efforts will be made to address and control cell survival and death. The aim, to develop a (photo) synthetic cell factory, will have an enormous impact on the future options and possibilities for renewable solar fuel production. The consortium includes academic, research institute and industry participants with the direct involvement of two SMEs in the advanced photo bioreactor design, construction and use. Purpose-designed, specifically engineered self-sustained cells utilising solar energy and CO2 from the air, may be the mechanisms and processes by which we generate large scale renewable energy carriers in our future societies. CyanoFactory offers Europe the possibility to take a lead, and not only follow, in these very important future and emerging technologies!

Partners:

- Uppsala University, Sweden

- University of Applied Sciences Mittweida, Germany

- Instituto de Biologia Molecular e Celular, Portugal

- Ruhr-University Bochum, Germany

- University of Ljubljana, Slovenia

- University of Sheffield, United Kingdom

- Universidad Politécnica de Valencia, Spain

- KSD Innovation GmbH, Germany

- Consiglio Nazionale delle Ricerche, Italy

- M2M Engineering sas di Diano Marcello Maria, Italy

Funding

Dec. 1 2012 – Nov. 30 2015 by the European Commission, FP7 / Energy Contract 308518

KSD Laboratory photo bioreactor

Our photo bioreactor is a plant for the production of micro-organisms outside of their natural habitat and in artificial and technical environment. These bioreactors cultivate phototrophic organisms, which use light for their own energy recovery and build up their own biomass of light and CO2. These organisms include e.g. microalgae and cyanobacteria.

The main goal of our photo bioreactors is the control of the habitat for the optimal living conditions for each organism with an online control program developed by KSD. In comparison to the environment the photo bioreactors achieve a significantly higher growth rate and purities.

The flat panel photo bioreactor (FPBR) in the figure is because of its used material which is polymers and the possibility to produce most of the parts by milling a low-cost reactor. This applies for a lot size of ten pieces. If more reactors are manufactured the costs will be even lower. Furthermore, this type of reactor has some advantages in its use. Due to the small thickness of the reactor the culture can be optimally mixed thus the existing algae receive the same intensity of light in the entire reactor. In addition, the reactor can be opened, cleaned and reused.

Similarly, the reactor can be chemically sterilized. A new process for the sterilization of the reactors has been developed and tested in this project.

Basic concept

The reactors use standard connectors G ¼” for liquid and gas. These connectors are available in different sizes. Fits to the adapters, O-rings are used. The screws are another standard element which is used in the polymer material. Two electrodes with a standard PG 13.5 default port are provided.

The lighting of the reactors is done with LEDs. Thus, the lighting can be selected flexibly for example the wavelength. The intensity is regulated via the integrated lighting control through the online program.

The standardized reactors ensure that comparable results are delivered for the user. This could also deliver more comparable research results if different laboratories use the equal reactor (start: Germany, Japan and Korea).

Specifications of the reactors

- Specifications of the 1l reactor

- Specifications of the 5l reactor

- Specifications of the 100l reactor